Custom industrial software design and development

Designing software and distributed IT architectures is essential for creating scalable and efficient systems. My focus is on developing robust architectures that ensure seamless integration and optimal performance.

Analyzing information processes and data is key to understanding an organization’s needs. I thoroughly examine workflows and system interactions to identify areas for improvement and innovation.

Selecting the most suitable technologies is crucial. By staying informed on the latest advancements, I implement technologies that best meet project requirements, ensuring relevance and future-proofing.

Creating functional diagrams, MOM mapping, and User stories, along with estimating implementation times, are vital for effective project planning. These tools help visualize the project’s scope and create a clear development roadmap.

Coordinating development teams involves breaking down activities into tasks and closely monitoring progress. This ensures alignment with project goals and timely delivery of the final product.

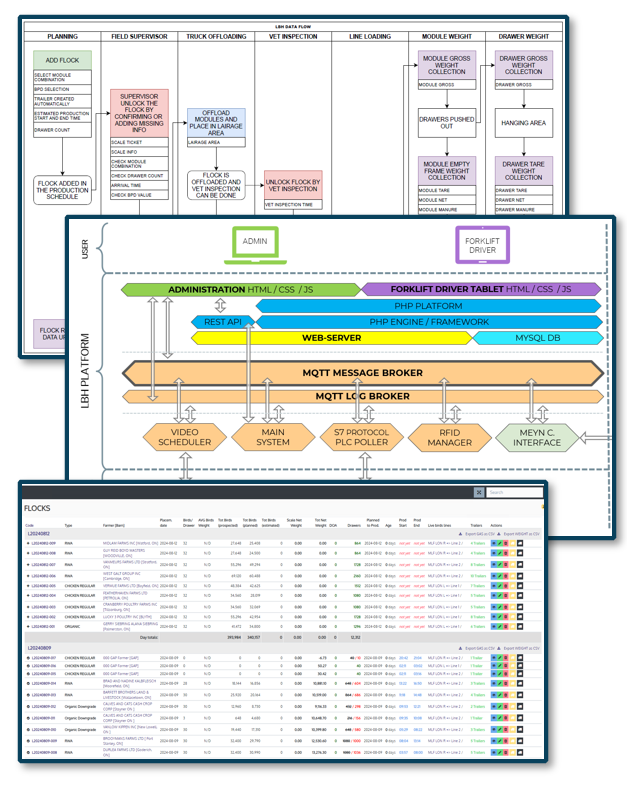

CASE 1) MEYN LBH

Design and development of a comprehensive platform for managing the planning, transportation, and reception of live animals in the poultry industry.

I personally designed and developed the initial deliverable of the software, known as LBH, which is now maintained and further developed by a dedicated team of two specialists. The platform was engineered to streamline and optimize the entire process, from scheduling to logistics and final delivery, ensuring efficiency and traceability throughout the supply chain.

LBH is currently in use by leading international companies in the poultry sector, including Maple Leaf foods, Indrol, Padesa, Cargill, and OfTov, reflecting its robustness and adaptability in meeting the complex needs of this industry.

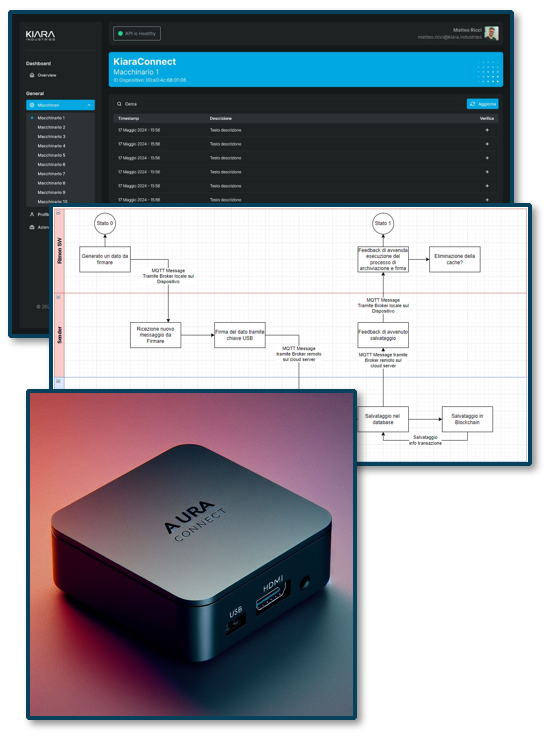

CASE 2) AURA CONNECT PLATFORM

Kiara Industries (of which I am a co-founder) is a leading company in Italy for the collection and secure signing of industrial process data using Blockchain technology.

The AURA Connect system, which I personally designed and is being developed by our in-house team, gathers data from PLC and CNC machines and securely signs it on the blockchain, ensuring tamper-proof integrity.

This patented process allows clients to produce legally valid data, even in court, which is invaluable for creating robust quality certificates or defending against defects and non-compliance issues.

This project requires that the final result be in the form of physical hardware.