Industrial software design and development

I design, implement, and supply advanced software systems for monitoring and analyzing production processes. My focus is on tracking Key Performance Indicators (KPIs), identifying inefficiencies, and enhancing productivity and yield.

I collect, store, and analyze process data to provide valuable insights into operations. By pinpointing inefficiencies and monitoring KPIs, I help businesses optimize resources and reduce costs.

I also create detailed reports, tables, and charts, along with Business Intelligence dashboards that turn raw data into actionable insights. These tools enable real-time tracking of performance, driving continuous improvement.

My real-time supervision dashboards offer immediate visibility into the status of production plants, allowing for quick issue identification and optimal efficiency.

Additionally, I develop production management tools for handling product data, defining phases and cycles, and tracking batches and orders. Through real-time data acquisition and seamless machine communication, I ensure that every aspect of the production process is optimized for higher productivity and yield.

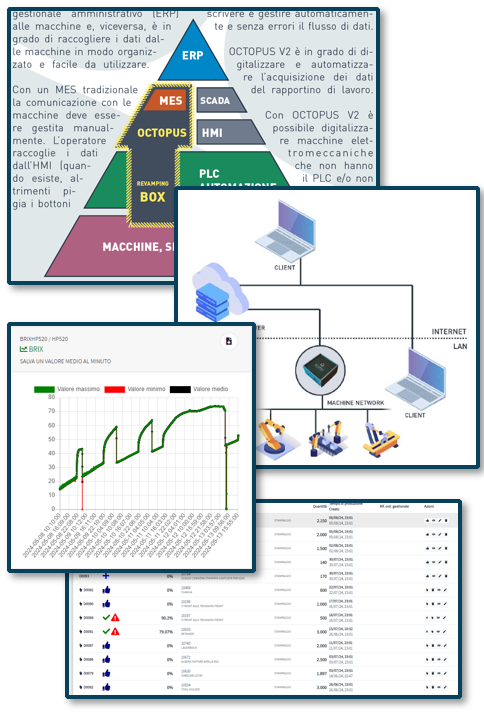

OCTOPUS THE M.E.S. DESIGNED FOR MEDIUM AND SMALL MANUFACTURING COMPANIES

Crossover Software, a company I co-founded, has been producing and distributing Octopus since 2016, an innovative, non-invasive MES (Manufacturing Execution System).

Octopus is cloud-based, cost-effective, and accessible, making it ideal even for small manufacturing companies operating under the Job Shop model. Although designed for a broad range of manufacturing needs, it has been successfully sold across the European market.

Octopus is currently used by over 150 manufacturing companies, with more than 700 industrial machines connected to it, following the Industry 4.0 paradigm.